/ 01/03/2024

SCADA software and HMI interface

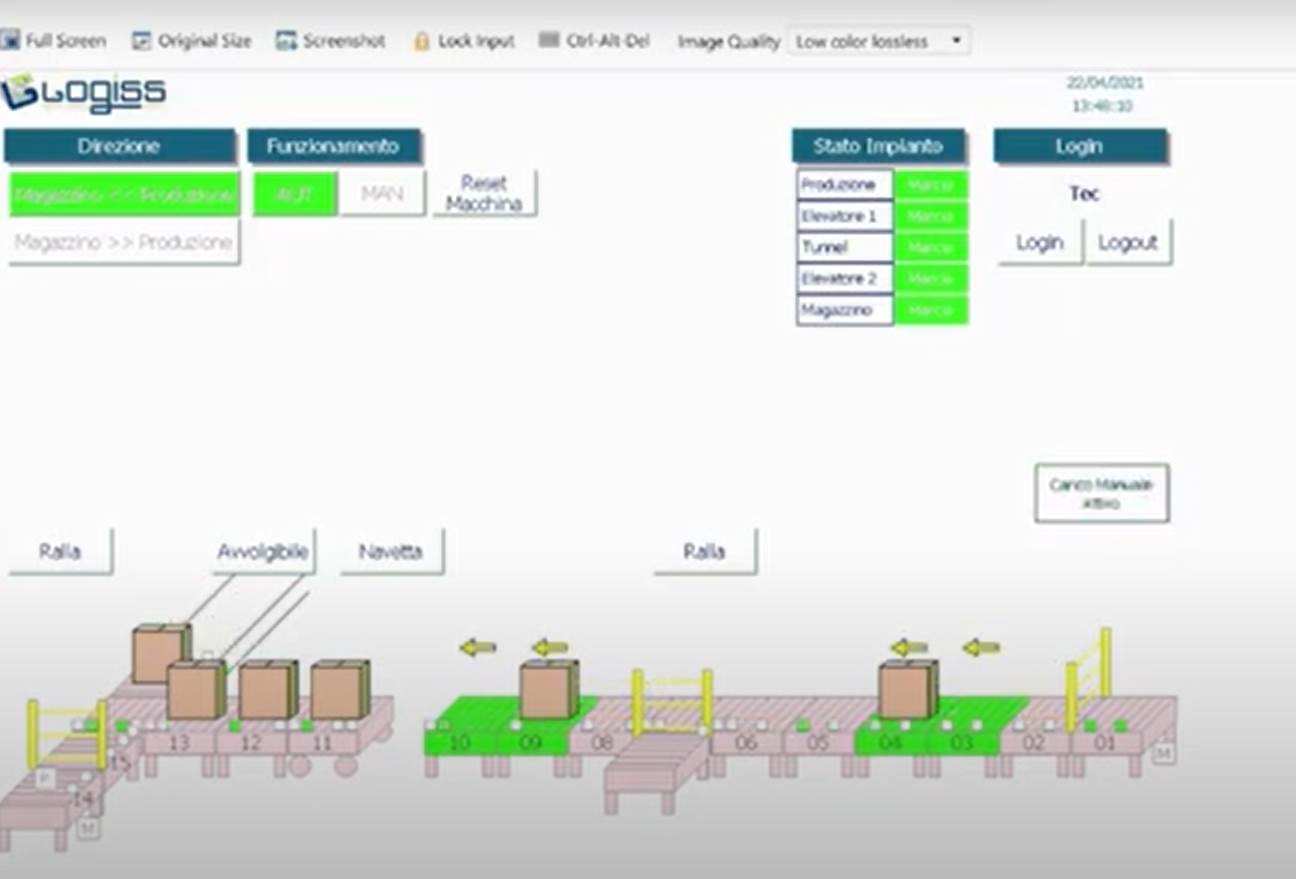

All Logiss systems are managed by SCADA software with a customised HDI interface. SCADA (Supervisory Control and Data Acquisition) software with HMI (Human-Machine Interface) for PLC (Programmable Logic Controller) is an advanced solution for monitoring and controlling complex industrial processes. This combination effectively integrates the power of PLCs with the accessibility and user-friendliness of the graphical user interface.

The HMI, often referred to as HDI (Human-Device Interface), provides an intuitive and detailed view of the system status, allowing operators to interact with the process efficiently. Through clear and customisable screens, users can view and analyse data from the PLCs, monitor crucial variables and respond promptly to any anomalies.

SCADA software acts as a crucial bridge between the PLC and users, ensuring smooth, real-time communication. Its ability to collect, process and present operational data enables complete system supervision. Customisable alarms and notifications alert operators to critical situations, allowing them to make timely decisions to ensure the safety and efficiency of the production process.

A key aspect of the HMI is its flexibility and adaptability to the specific needs of the user and the industrial process. The ability to customise screen layouts, integrate graphics and reports, and define quick commands provides an optimised and focused working environment.

In addition, the ability to record and archive historical data allows in-depth analysis of system performance over time. This facilitates process optimisation, the identification of trends and the forecasting of preventive maintenance.

In conclusion, the integration of SCADA software with an HMI interface for PLCs represents a significant step towards operational efficiency and advanced industrial process management. The combination of control power, ease of use and data analysis capabilities gives operators the tools they need to make informed decisions and ensure the success of the production system.

The HMI, often referred to as HDI (Human-Device Interface), provides an intuitive and detailed view of the system status, allowing operators to interact with the process efficiently. Through clear and customisable screens, users can view and analyse data from the PLCs, monitor crucial variables and respond promptly to any anomalies.

SCADA software acts as a crucial bridge between the PLC and users, ensuring smooth, real-time communication. Its ability to collect, process and present operational data enables complete system supervision. Customisable alarms and notifications alert operators to critical situations, allowing them to make timely decisions to ensure the safety and efficiency of the production process.

A key aspect of the HMI is its flexibility and adaptability to the specific needs of the user and the industrial process. The ability to customise screen layouts, integrate graphics and reports, and define quick commands provides an optimised and focused working environment.

In addition, the ability to record and archive historical data allows in-depth analysis of system performance over time. This facilitates process optimisation, the identification of trends and the forecasting of preventive maintenance.

In conclusion, the integration of SCADA software with an HMI interface for PLCs represents a significant step towards operational efficiency and advanced industrial process management. The combination of control power, ease of use and data analysis capabilities gives operators the tools they need to make informed decisions and ensure the success of the production system.