/ Handling of packages and boxes

Accessories and picking systems

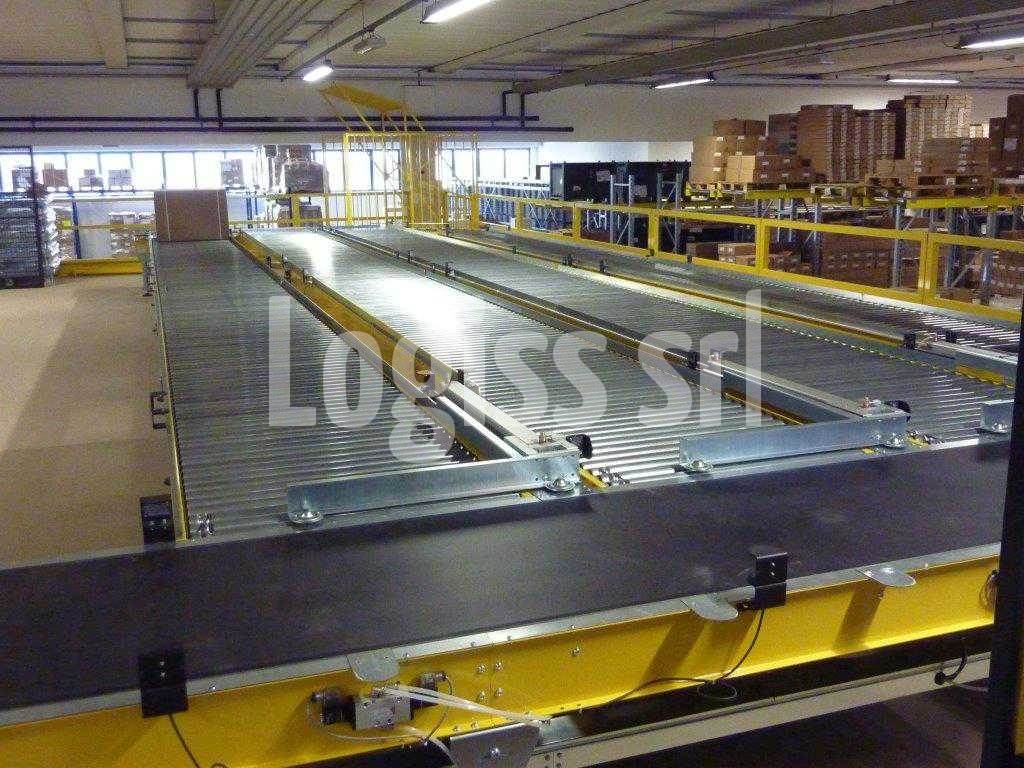

Logiss picking systems for warehouses are designed to streamline any preparation for shipment or goods sorting processes. Each project is built based on the client’s actual needs.

Following is an example of a picking system for warehousing.

Following is an example of a picking system for warehousing.

Caratteristiche principali:

Example of sorting system with swivel sorter

Example of sorting system with pop-up sorter

Indicative sorter size

53x5.5 m

25x11,5 m

Performance

3600 packages/h sized maximum 300x600x300 mm

-

Feed systems

extensive feed systems so as to reach all packaging stations

dual feed systems (incoming branch from case packer and branch for manual packaging)

Rate achieved via stepper motors and via speed changes

Pre-set

-

for additional direct loading boxing machine (third feed path)

Rate achieved

via stepper motors and via speed changes

via stepper motors and flow merging

Scanner for label reading

top-side

2 sides (top and 1 side)

Sorting

via swivel sorter modules and pre-sorting system (alignment on right/left side of main path based on defined exit point)

with 8 pop-up sorter modules

Buffer module

-

in case of presence of load-bearing column in industrial building

Exits

9 m exits, of which 6 m belt-driven with transversal belt for accumulation and 3 m with gravity roller conveyor

9 m exits, of which 6 m belt-driven with transversal belt for accumulation and 3 m with gravity roller conveyor

Alerts

-

"chute too full" alerts

Final exit for unread packages

yes

yes