/ 17/01/2024

A new special project in Greece told by Logiss project manager

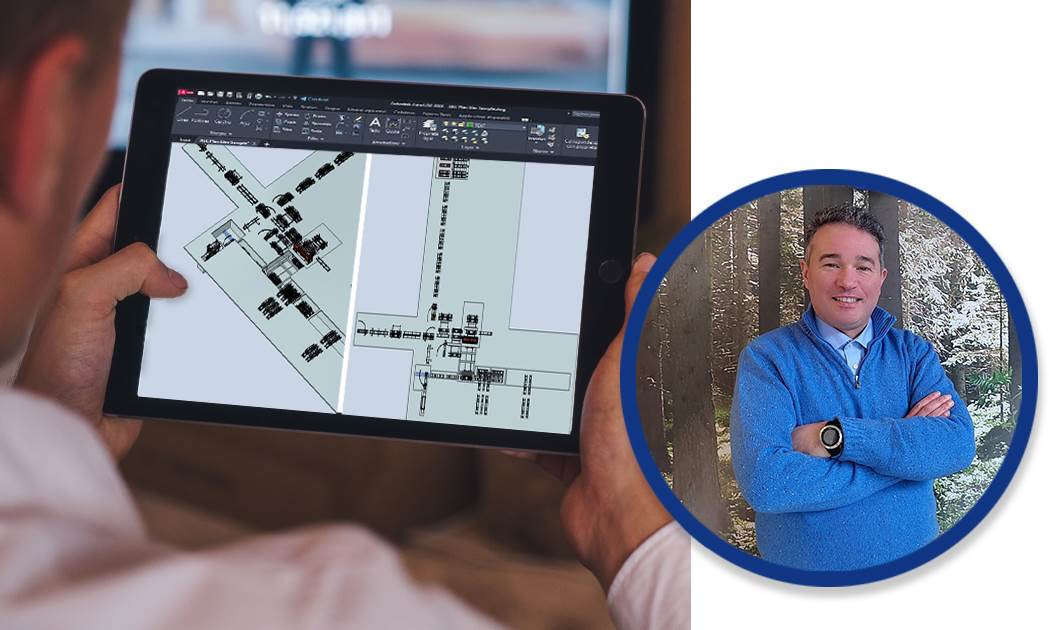

In recent months Logiss has completed an important project in Greece involving the construction of a complex catenary system for handling aluminium profiles. Coordinating the development of the technical project was Fabrizio Gasperotti, Head of Engineering at Logiss srl.

In Logiss since 2022, Fabrizio Gasperotti manages a team of 13 designers thanks to a solid career developed in the food industry where he gained a deep understanding of the complexities involved in the design of internal handling systems.

The project in question involved the realisation of a special handling system designed to handle baskets containing aluminium profiles with a maximum length of 7.5 metres and a maximum weight of 2300 kg. The main challenge for the design team was to handle these considerable dimensions efficiently and safely.

What were the main technical challenges faced during the design and implementation of this installation?

The main challenge was to design a system of 100 machines that could handle the specific dimensions and weights of the baskets to be rotated, lifted and changed direction safely and efficiently. We had to develop new catenary machines, including deflectors, fifth wheels and elevators, in order to ensure precise movements and safe operations.

What innovative solutions have been adopted to overcome these challenges?

We introduced advanced technologies in the deflectors and turntables to ensure smooth and precise movement of the baskets. The elevators have been designed with automatic control systems that adapt to the specific dimensions of each basket. In addition, we implemented advanced safety systems to protect both operators and material during handling operations.

How was the complexity of the logistics and installation of the plant managed at the site in Greece?

Logistics management was a key part of the project. We carefully planned the shipment of all plant components and coordinated the installation activities with local personnel. Our team of technicians worked closely with the Greek personnel to ensure a smooth installation and quick start-up of the plant.

What were the results achieved with the implementation of this special handling plant?

The implementation of the system has led to a significant increase in the efficiency of basket handling. Precise movements and safe operations have improved significantly, contributing to the overall success of the project and customer satisfaction.

In Logiss since 2022, Fabrizio Gasperotti manages a team of 13 designers thanks to a solid career developed in the food industry where he gained a deep understanding of the complexities involved in the design of internal handling systems.

The project in question involved the realisation of a special handling system designed to handle baskets containing aluminium profiles with a maximum length of 7.5 metres and a maximum weight of 2300 kg. The main challenge for the design team was to handle these considerable dimensions efficiently and safely.

What were the main technical challenges faced during the design and implementation of this installation?

The main challenge was to design a system of 100 machines that could handle the specific dimensions and weights of the baskets to be rotated, lifted and changed direction safely and efficiently. We had to develop new catenary machines, including deflectors, fifth wheels and elevators, in order to ensure precise movements and safe operations.

What innovative solutions have been adopted to overcome these challenges?

We introduced advanced technologies in the deflectors and turntables to ensure smooth and precise movement of the baskets. The elevators have been designed with automatic control systems that adapt to the specific dimensions of each basket. In addition, we implemented advanced safety systems to protect both operators and material during handling operations.

How was the complexity of the logistics and installation of the plant managed at the site in Greece?

Logistics management was a key part of the project. We carefully planned the shipment of all plant components and coordinated the installation activities with local personnel. Our team of technicians worked closely with the Greek personnel to ensure a smooth installation and quick start-up of the plant.

What were the results achieved with the implementation of this special handling plant?

The implementation of the system has led to a significant increase in the efficiency of basket handling. Precise movements and safe operations have improved significantly, contributing to the overall success of the project and customer satisfaction.